All research collected is secondary and has been collected from the official 'Windowfarms' website.

I started collecting further research into the company as it has a lot relevance to my brief. I started by watching a ted-talk from the companies founder and CEO Britta Riley.

Important points made;

- Michael Palin - growing even some of our own food is one of the best things you can do for the environment.

- Hydroponics used for growing food in space.

- Windofarms - vertical, hydroponic, indoor food growing system.

- Started off as D.I.Y project.

- Monsanto have laws regarding growing and controlling food.

- Company made open source to help develop product - R'n'D.I.Y (research & develop it yourself).

- Free instructions available so that anyone, anywhere in the world can create a D.I.Y version of the product.

- Projects contributes to the environmental movement.

ABOUT THE COMPANY

- The company that focuses on helping city dwellers around the world grown fresh, nutrient rich vegetables in the comfort of their own urban environment.

- Windowfarms makes vertical indoor food gardens that optimise the conditions of a window and make it suitable for year-round growing.

- The company has a huge online community and aims to spread the word about urban agriculture its benefits.

- The project runs a D.I.Y version along side the commercial windowfarm that is sold onsite.

- The D.I.Y version of the product has been slowly developed and redesigned through the application of an opensource company, which basically gives users production information for free and allows for feedback regarding the design and application of the product. The feedback process allows for a range of informed input from a variety of people, information is then reviewed and applied to improve the overall functionality of the product.

- The opensource concepts also creates a big online community where users can interact and swap information regarding the various aspects of the production and maintenance of the product.

- The project began as an experiment into developing environmentally friendly urban growing solutions but eventually transformed into an open source business.

- Founder Britta Riley created the first windowfarm back in 2009, since then through open source collaboration and development a window hydroponic food growing system has been developed.

- There is a D.I.Y section of the site where set-by-step instructions walk users through how to build their own window farm from recycled materials.

- Windowfarms have developed a commercial product which is now on the market thanks to an online start-up campaign that raised over $285 000.

- Due to its open source concept company has a huge online community consisting of over 40,000 members from across the globe.

- The current focus of the community is to give advice on the production and maintenance of the D.I.Y windowfarms, however there is currently a shift occurring where the community will focus on sharing information regarding vegetable growth, nutrients and micro climate conditions.

PRODUCT

Below are images of the windowfarm's available products, an aspect of the company that really inspired me to collect further research into it is the fact that the company offers both the product, but also detailed guidelines and supporting information on how to build a D.I.Y version.

OVERVIEW

HOW IT WORKS

- The system works by pumping nutrient rich water up from a reservoir at the base of the system, the water is pumped up to the top bottle so that gravity pulls it past the roots and down through to the next container. Plant roots do not sit in soil, but instead in a root nest that is made from coconut hair, rice hulls and clay pellets infused with symbiotic microscopic life. Any water and nutrients that are not absorbed are pumped through the system to the next bottle.

- Very cheap to run as they run an a timer.

- Pumps used to grow high maintenance crops such as the cherry tomato require the pumps activation more regularly. Therefore, high maintenance crops require slightly more electricity.

- A four-column windowfarm uses around $3.16 per year to run in America.

- The low electrical usage of the units directly relate to my target audience who are environmentally aware

- Different versions of the product have been created so that the windowfarm can be applied to the varying size of windows found within the audiences environment.

- Bioponic is an emerging field that combines the advantages of hydroponic liquid nutrient feeding with organic natural inputs and root system ecology.

- The windowfarms company has been on a quest to produce the best tasting, nutritional food that use the lowest amount of resources and input.

- Microbes work with other sustainable materials to help plants and vegetables take in all the nutrients they need to grow healthily.

- Windowfamrs are more suited to using nutrient-rich, organic and ocean plant foods that can compromise more high-tech growing systems.

- The specially designed root nest helps to create an ecosystem that helps plants digest all the nutrients and food they need.

- Organic nutrients bring a diversity of nutrients and minerals that are often missing from more industrial produce. - Facts like this could be used in the advertising campaign.

- By using air pumps, with no mechanical parts to clog, the systems are far less susceptible to pump failure.

WINDOW FARM COMMERCIAL PRODUCT

Below are images of the commercially available single column Windowfarm product.

- Once the commercially available product has been built and all the plants planted it will look like the image above displaying a single column windowfarm.

- Images like the one above work well at showing the audience individual pieces of the product that form the final outcome.

WHAT GROWS WELL

Also available on the 'Windowfarms' website was a list of vegetables, fruits, herbs and flowers that grow well using a windowfarm. The list was composed of elements that members from the 40, 000 strong online community had suggested grow well, therefore all information is very reliable.

BUILD YOUR OWN

The 'build your own' section of the website is the area I want to focus most of my research. The D.I.Y aspect of the company applies directly to my re-written brief and initial concept of providing my target audience with a way to grown food in an urban environment.

There are two D.I.Y variations of the windowfarm, one hangs in the window and the other works by standing on a bottle. Each version has its own benefits relating to space and window size, this helps to eliminate problems regarding the varying space people have when living in an urban environment.

VERSION 3 - Hanging column windowfarm.

To attain the information on the resources needed and how to build the farm I had to become a member of the community and agree to the terms and conditions.

Once I became a member of the community I was directed to the step by step instructions which walk users through the production process of a hanging windowfarm.

The production of the system is split into ten sections;

- Bottle covering.

- Plant bottle.

- Reservoir bottle.

- Suspensions system.

- Mounting and installation.

- Pluming system.

- Adding lights.

- Adding plants.

- Full assembly.

- Maintenance.

Moreover, there were also additional downloads such as the 'parts list' and 'bottle cutting templates'.

PARTS LIST

The parts list was available as a PDF. download, it lists all of the items needed for the complete production of the D.I.Y windowfarm. A benefit of distributing the 'parts list' by a PDF file format is that there is no resources used to print or distribute it, as an environmentally driven company this is a very beneficial aspect.

The guide is not very aesthetically inviting and looks very formal for such an creative forward thinking company. I think that the company would benefit from a re-brand to make them more appealing to possible users.

- The simple design is easy to follow but very text heavy.

- The only recycled parts that the guide lists are the plastic bottles.

- In the footnotes the guide lists how certain parts can be made from recycled materials rather than bought from a hardware store, this would be relevant to the members of my audience who don't have a lot of money but still want to grow their own food.

BOTTLE CUTTING TEMPLATES

Another PDF. download made available to users are the two bottle cutting templates, released to help consistently cut the holes into the various bottles of the windowfarm. The idea is really functional and relevant as it provides users with illustrative instructions on how to use the template which allows users to accurately cut each bottle.

- The templates provide the audience with simple graphic illustrations that help to instruct the user so that they can effectively utilise the template.

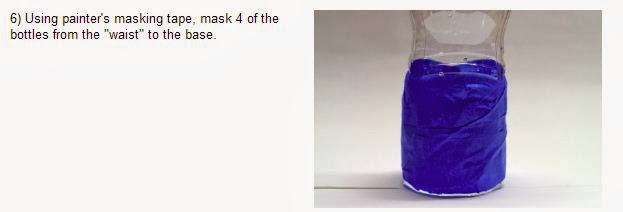

STEP 1 - BOTTLE COVERING

The first step of the process involves the preparation and covering of the plant bottles.

The first step of the process involves the preparation and covering of the plant bottles.

STEP 3 - RESERVOIR BOTTLE

STEP 4 - SUSPENSION SYSTEM

STEP 5 - MOUNTING & INSTALLATION

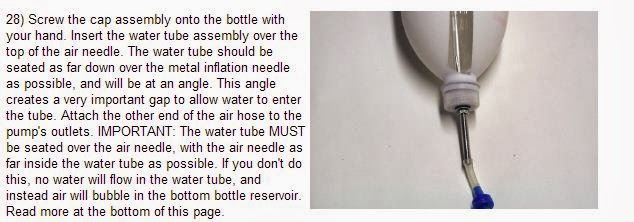

STEP 6 - PLUMBING SYSTEM

STEP 7 - ADDING LIGHTS

STEP 8 - ADDING PLANTS

STEP 9 - FULL ASSEMBLY

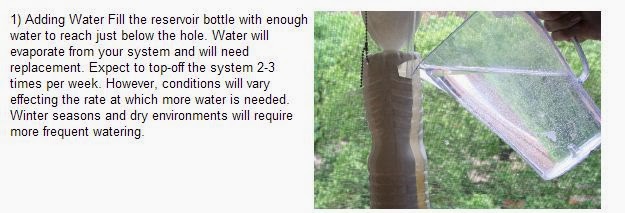

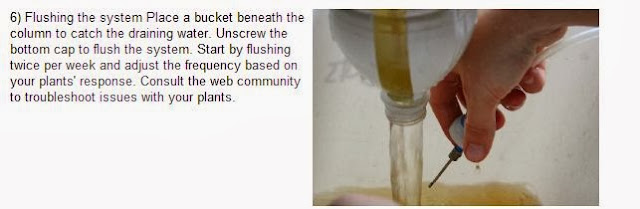

STEP 10 - MAINTENANCE

CONCLUSION

I initially started collecting research into the 'Windowfarms' company to see if I could take aspects from their product and business to help strengthen my initial concept. When generating initial responses to the problems set out by the brief I created a very similar looking concept that utilised recycled bottles and string to form growing columns. Shortly after this I discovered the Windowfarms company.

After discovering the company and seeing the similarities between my initial concept and their product I decided to analyzing their products and business model in hopes that I could take aspects from their company to help develop the functionality and relevance of my product.

However, after analysing the company I soon realized that Windowfarms had essentially already created and developed my initial concept to a much higher level that I could have hoped to achieve with the small amount of time available for the project. The basic idea for the vertical column window farm was almost identical to the one developed by Windowfarms, however, theirs, with the addition of a bioponic growing system is far more advanced.

I initially looked to Windowfarms as a way of developing my initial concept to make the product more functional. However, after reviewing the Windowfarms company the sweeping realization came over me that I couldn't develop my product any further because Windowfarms have already done so. They have variations of the product so that space is not a problem, and have put a lot of thought into the bioponic feeding system that accelerates plant growth and health. I was weeks of research away from developing my product to that sort of level, and even then it would essentially be an identical outcome.

Therefore, as the company have a far more advanced working version of my initial response I have decided to instead use Windowfarms as a platform for the rest of my project. Instead of developing, promoting and branding my own D.I.Y growing product I will simply promote and brand the D.I.Y aspect of the windowfarms company, this will save me a huge amount of time as now the majority of the research and product development is already done.